Offering a Comprehensive Line of Fluid Transfer Products and Custom Manufacturing Services

The Specialty Mfg. Co. is a vertically integrated company of five divisions offering metal and plastic valves, quick disconnect couplings, dental components, pool/spa chemistry automation, custom machine tool fixtures, contract manufacturing solutions, and design and fabrication services.

Mechanical Valves

Quick Couplings

Contract Manufacturing

Design & Fabrication

Manufacturing in the U.S. allows us to cut down on lead times and supply chain disruptions, providing a more seamless experience for our customers.

Our Products

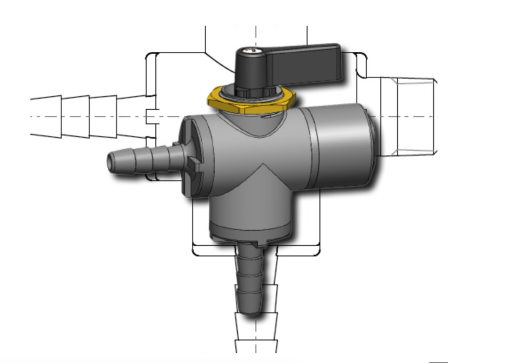

A Leading Manufacturer of Valves Under One Inch

Stock and Modified Valves for Pneumatic and Fluid Control Applications

The Specialty Mfg. Co. manufactures valves and check valves in brass, stainless steel and plastic. All products are proudly made in the U.S.A. in an ISO 9001:2015 Certified facility. The valve product line includes:

- Custom Valves

- Check Valves

- Ball Valves

- Needle Valves

- Miniature Valves

- Push Button & Toggle Valves

- Accessories

Find Your Solution Using Our Valve Configurator!

Our Products

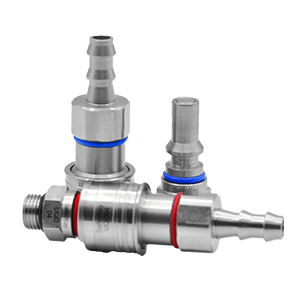

Solving Fluid Transfer Challenges Since 1969

Custom and ISO Standard Quick Couplings

SafeWay couplings are manufactured to specific ISO standards and we can execute custom solutions in the size, material, and finish your application requires. All products are proudly made in the U.S.A. in an ISO 9001:2015 Certified facility. Quick disconnect couplings in our product line include:

- Thermal Management & Liquid Cooling Couplings

- Threaded Connection Couplings

- ISO 7241 A & B Couplings

- ISO 5675 Couplings

- ISO 16028 & Flush Face Couplings

- Accessories

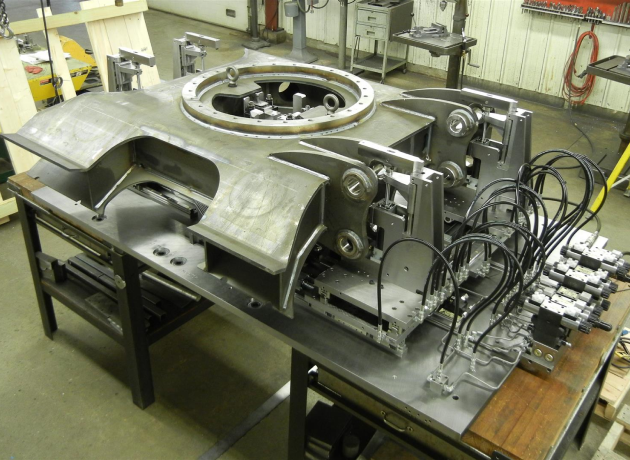

Our Services

Custom Manufacturing Solutions, Design & Fabrication

The benefit of working with a vertically integrated company is access to a breadth of services, all handled by one team working together for you. We design, engineer, and manufacture solutions for applications across all industries using state-of-the-art equipment and technology.

Our people-first approach means you can count on a response within one business day of your initial request.

Precision Machining, Molding, and Assembly Services

Custom Design and Fabrication Capabilities

Industries Served

Stock and Modified Products and Custom Solutions for Virtually Every Industry

Agriculture

Chemical Dispensing

Cleaning & Janitorial

Food & Beverage

Industrial

Power Generation

Pressure Wash/Car Wash

Thermal Management

Water Filtration

The Latest Company News and Industry Knowledge

Preventing Downtime: Common Valve Issues in Car Wash Systems

Downtime is a costly problem for any business, and car washes are no exception. When customers can’t access soap or when wastewater systems fail, it can lead to expensive losses. Regular customers and first-time...

Helping Cruise RO Water Simplify Marine Refrigeration Systems

SafeWay, a division of The Specialty Mfg. Co., specializes in fluid control and quick disconnect solutions for a variety of industries. One of our valued customers, Cruise RO Water and Power, manufactures marine...

Celebrating 125 Years of Innovation

2025 marks the 125th anniversary of The Specialty Mfg. Co. As we reflect on this monumental milestone, we will take a look back at the incredible work ethic and leadership that shaped our beginnings and continues...

Over a Century of Service and Innovation

Founded in 1900, the Specialty Mfg. Co.’s products and capabilities have expanded from manufacturing valves to a complete offering of quick disconnect couplers, dental components, pool/spa chemistry automation, custom machine tool fixtures and contract manufacturing solutions.