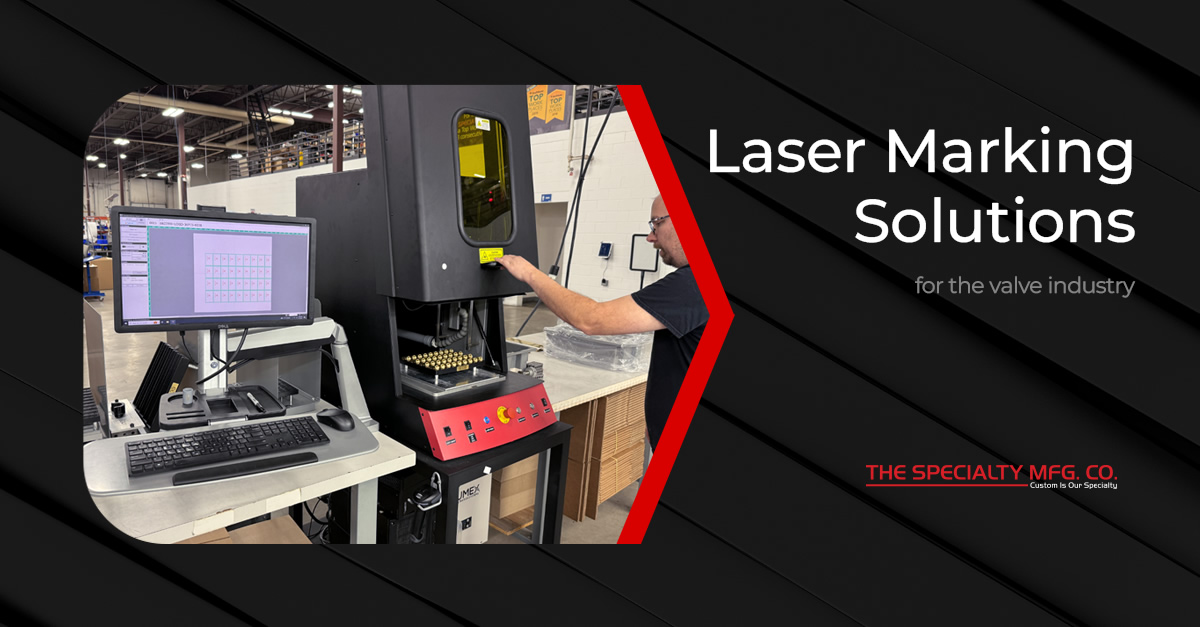

Laser Marking Solutions for the Valve Industry

Laser marking stands out as a superior solution for valve industry needs, offering a range of advantages, including branding, identification codes, warning labels, and user instructions. Unlike traditional marking techniques such as pad printing,...

Custom Valve Streamlines Customer Assembly

Challenge: Streamline Operations and Enhance Efficiency Holiday House Distributing, North America’s leading distributor of office coffee service (OSC), water, and vending parts faced inefficiencies while integrating The Specialty Mfg. Co’s stock...

Tailored Engineering Meets Miniaturization Requirements While Containing Costs

Challenge: Engineering for Reliable Diesel Exhaust A global diesel equipment manufacturer faced a challenge when they needed to reduce the size of a valve on a diesel exhaust system. This change necessitated sourcing smaller valves that could fit...

Employee Spotlight: Brad Stadick

Name, title and how long you’ve been at Specialty Manufacturing Co. Brad Stadick, and I have been a machinist with Specialty Manufacturing for one year. Describe what your department is responsible for. What tasks are done daily? Our department is...

Custom Solutions for Backflow Prevention

Challenge: Addressing fuel line backflow in industrial equipment A major industrial equipment manufacturer encountered significant challenges with fuel line backflow in their forklift tractors, prompting a search for a more effective valve solution...

Employee Spotlight: Connie Walerius

Name, title and how long you’ve been at Specialty Manufacturing Co. ConnieWalerius, Quality Engineer. 19 years What is your role at the company, and what does a typical day look like for you? Quality Engineer – I support all business units for...

Committed to Environmentally Friendly Manufacturing

Operating an environmentally friendly production facility requires a focus on two key areas: reducing energy consumption and responsible waste management. These two pillars provide the structure and commitment to eco-friendly business practices, a...

Employee Spotlight: Lance Junker

Name, title and how long you’ve been at Specialty Manufacturing Co. Lance Junker, Shop Supervisor, 5 months Describe what your department is responsible for. What tasks are done daily? I am part of a 17-person team consisting of CNC Specialty...

Case Study: Push-button Relief Valve

Challenge: Redesigning a Replacement Valve for Aerospace Application In response to a need within the aerospace industry, a customer needed to find an alternative source for a custom push-button relief valve used in helicopter seats. The abrupt...

Employee Spotlight: Justin Howlett

Name, title and how long you’ve been at Specialty Manufacturing Co. Justin Howlett, almost five years, Lead Injection Molding Set-Up Tech. What is your role at the company, and what does a typical day look like for you? A typical day includes...

Three Factors in Selecting a Valve Material for Your Fluid Transfer System

When it comes to selecting or designing a valve, selecting the right material is crucial for ensuring efficiency, longevity, and safety. Factors like operating pressure, temperature fluctuations, and fluid type all affect valve performance. If a...

Employee Spotlight: Jolene Kohler

Name, title and how long you’ve been at Specialty Manufacturing Co. Jolene Kohler, Buyer for Valve Division, SafeWay and Integrated Services. I’ve been at Specialty for 3 Years. What is your role at the company, and what does a typical day look...

Employee Spotlight: Ryan Clobes

Name, title and how long you’ve been at New Ulm Precision Tool, a division of The Specialty Manufacturing Co.? Ryan Clobes, Machinist, 17 years Describe what your department is responsible for. What tasks are done daily? Machine parts for...

Employee Spotlight: Sales Manager Darrin Bergman

Name, title and how long you’ve been at Specialty Manufacturing Co. Darrin Bergman, Integrated Services Sales Manager. I’ve been a member of the Sales Team at Specialty Manufacturing since October of 2022. What is your role at the company, and what...

Check Valve Types: How To Choose the Right Option for Your Fluid Power System

Is There a Difference Between A Check Valve vs. Ball Valve? While both apply to fluid control, there are significant differences in their design and intended application. Check valves, also known as non-return or one-way valves, play a...