Is There a Difference Between A Check Valve vs. Ball Valve?

While both apply to fluid control, there are significant differences in their design and intended application. Check valves, also known as non-return or one-way valves, play a crucial role in preventing backflow and ensuring efficient operations in fluid power systems. Among the check valve types – ball, poppet, or piston – each has unique features best suited for specific applications.

Ball valves, on the other hand, are designed to regulate flow and pressure. You often find this type of valve in pipelines or applications involving the control and shut-off of fluids and gases.

Check valves are highly versatile and used across industries ranging from chemical dispensing to agriculture. We’ll explore the key considerations when choosing a check valve for your fluid transfer system.

What Is a Ball Check Valve?

Ball valves feature a closing mechanism in the shape of a ball to block flow. The interior surfaces of the main seats are conically tapered for the ball to fit into, forming a positive seal that stops reverse flow.

- Applications: High-pressure applications, systems with high flow requirements, and the flow of viscous media.

- Considerations: Ball check valves are less suitable for applications that require fine-tuned regulation of fluid flow or have tight space parameters.

- Advantages: Simple and robust. The most economical valve option.

What Is a Poppet Check Valve?

Poppet check valves feature a moveable element, typically a disk or cone-shaped component, referred to as a poppet. The poppet is held in place by a spring or other mechanism, allowing it to move away from the seat when fluid flows and return to the closed position when there is backflow.

- Applications: Fluid transfer systems, such as chemical or laundry dousing systems, where accurate regulation of fluid flow is necessary.

- Considerations: This style is not ideal for low-pressure conditions where the spring force may overcome the pressure of the fluid, resulting in partial closure and potential backflow. Poppet check valves can have higher friction loss and should be considered if minimizing pressure drops is critical.

- Advantages: Accurate and reliable. Poppet check valves have a smaller overall size when compared to ball or piston check valves.

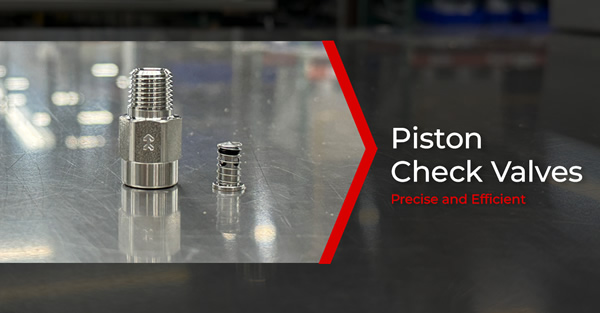

What Is a Piston Check Valve?

Piston check valves utilize a piston or disk housed within a cylinder to control the media flow. The piston is lifted, allowing flow, and forced back into the closed position in the presence of reverse flow.

- Applications: Low flow rates and situations where positive closure is crucial.

- Considerations: Potential for sticking or sluggish movement if debris or contaminants are found in the transfer media. Higher friction loss should also be considered with Piston check valves.

- Advantages: Precise and efficient fluid control.

Addressing Your Fluid Control Challenges

Ball, poppet, and piston check valves are each engineered to address specific fluid control challenges. Understanding your fluid system, existing components, and environment will help drive the decision on which check valve will provide the best results. Read and download Check Valve – A Tutorial for more information about check valves.

Complete Check Valve Solutions

With more than one hundred years of design and manufacturing experience behind us, The Specialty Mfg. Co. offers a broad range of metal and plastic check valves, pneumatic check valves, and one-way check valve options, and numerous other valves and related components.

Our in-house operations and expertise in manufacturing allow us to meet our customers’ needs, whether they are stock items or fully custom parts. Use our 3D valve configurator to design your valve, or contact our sales team to discuss custom valve solutions.