Laser marking stands out as a superior solution for valve industry needs, offering a range of advantages, including branding, identification codes, warning labels, and user instructions. Unlike traditional marking techniques such as pad printing, etching, or stamping, laser marking offers extreme precision and speed, leaves a permanent mark, and requires no consumables or maintenance. In this blog, we explore how this technology works, the types of materials that can be marked and the benefits of laser marking within the valve industry.

How Laser Marking Works

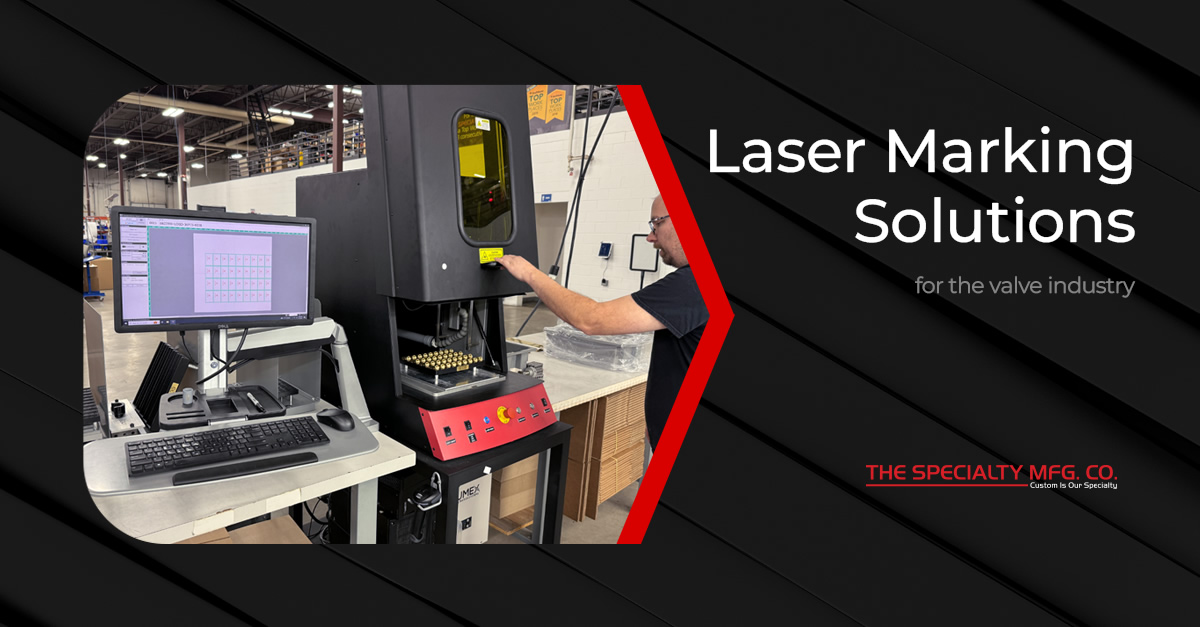

The process of laser marking uses a focused laser beam to create a high contrast, permanent mark. Unlike laser etching, which removes material to create the mark, laser marking uses light to discolor the part without physically altering the material. This non-contact process eliminates the risk of damage to valve components and allows for intricate designs and small font sizes. Equipped with intuitive software, operators customize the settings and program files to apply precise and consistent marking.

“Laser marking provides efficiency and speed in the world of industrial marking. With its precise capabilities, it streamlines the marking process, ensuring swift production without compromising on quality”, states Jesse Wagner, Continuous Improvement Technician.

Materials Suitable for Laser Marking

The versatility marking technology extends to a wide range of materials commonly used in manufacturing. These include metals such as stainless steel, brass, aluminum, and plastics like PVC, ABS, and PTFE. Whether the valve components are metallic or non-metallic, laser marking provides a durable and precise marking solution.

Benefits of Laser Marking

Major benefits of laser marking include high-speed capabilities, high precision, resistance to wear or harsh conditions and is eco-friendly operation.

Maximum precision: The focused laser beam allows the marking for fine details, intricate designs, and small fonts, making it ideal for marking small components.

No added material costs: Unlike pad printing or stamping, laser marking requires no consumables, promoting environmentally friendly practices and cost savings.

High speed: One of the most significant benefits is the speed at which the laser can process parts. Requiring minimal set up, multiple parts can be marked simultaneously, with no drying or cooling required.

Applications

Branding

One advantage of laser marking for valves is the ability to provide clear and permanent branding. Adding a logo or company name to a part increases brand awareness, aiding in identification for replacement needs, and adds an elevated high-end feel to a part.

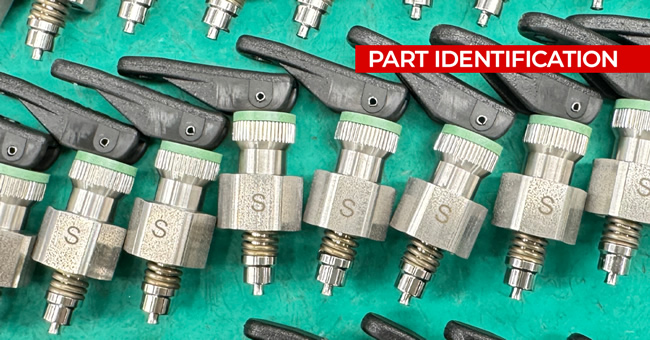

Part identification

Laser marking allows parts to be marked with unique identifiers, facilitating easy tracking and inventory management. This is particularly crucial in industries where precise part identification is essential for quality control and maintenance.

End use applications

Directional arrows, pressure limits, temperature ranges or other identifiers reduce the opportunity for end system errors. Laser marking enhances safety by enabling the inclusion of safety warnings, instructions, and compliance symbols directly onto the valve. These markings are resistant to wear, chemicals, and harsh environments, ensuring critical safety information remains visible and intact.

Incorporating laser marking in valve production not only enhances safety and functionality but also opens avenues for innovative applications and industry-specific solutions.

In conclusion, laser marking presents an innovative solution for the valve industry, offering benefits in branding, part identification, and safety. Its compatibility with various materials and precise marking capabilities makes it an indispensable tool for manufacturers aiming for efficiency, quality, and compliance in valve production.

At The Specialty Mfg. Co., we utilize innovation and technology to provide customers with efficient, cost-effective solutions. Laser marking is one of the many in-house manufacturing services that offers our customers innovative solutions to make their ideas a reality.

Learn more about our custom solutions.