The Starting Point of Turning Your Ideas into Reality

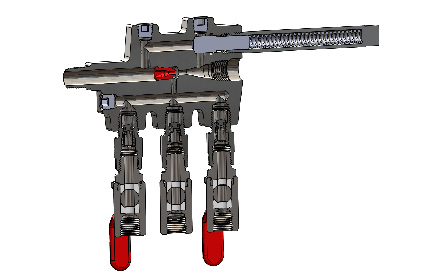

Manufacturing engineering and design is an essential element of our iterative process and where the best conversations happen. We collaborate with you on product design and design for manufacturability to ensure your part meets all aspects of function and dimensional integrity.

The Specialty Mfg. Co. is proud to be a USA-based company with a people-first commitment to customer service. Our facility is ISO 9001:2015 Certified to ensure quality throughout every stage of your project.

Specialized Engineering Support

We provide manufacturing engineering and design support for contract manufacturing and plastic injection molding projects. Customers we typically work with have a partial design or need guidance on the design for a part they have never manufactured before.

You will receive input and guidance based on our design engineering expertise and manufacturing know-how to help you achieve the most optimal result for your application.

An Opportunity to Test and Verify Your Part

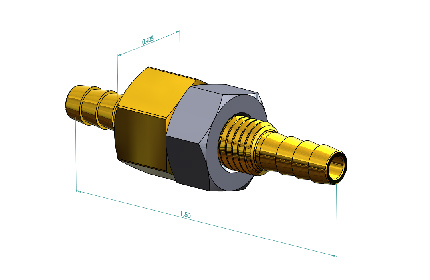

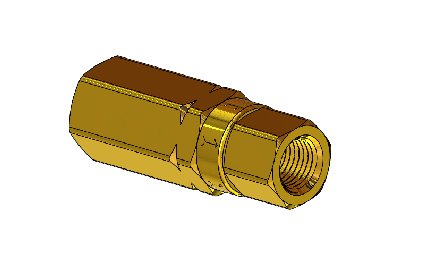

Prototyping allows you to test your part in the application before moving into final production. We utilize CNC equipment and 3D printing technology and have rigorous quality standards to ensure your prototype meets the exact specifications outlined in your print.

We also test prototypes internally before submitting them to you for internal review as part of our quality assurance process.

Our Engineering Process

Services Trusted by Manufacturers Worldwide

Consultation

Meet with our engineers to discuss your partial design and application.

Design Modifications

Design for manufacturability optimizes the dimensional integrity of your part.

Prototype

We use in-house CNC machining and 3D printing to supply a low-cost model to verify fit, function or aesthetics.

Explore Our Engineering Department!

Learn more about our engineering department and the technology used to make your ideas real.

Looking for something different? Our capabilities also include precision machining, plastic injection molding, contract assembly, and design and fabrication services for your project.

Contact Us to Discuss Your Project!

The Specialty Mfg. Co. is a fully integrated contract manufacturer offering machining, plastic injection molding, contract assembly, and value-add engineering. Call or send us a message to discuss your design and application!

Contact Information

Call Us

The Specialty Mfg. Co:

(651) 653-0599

New Ulm Precision Tool:

(507) 610-7770 or (800) 795-1229

SafeWay:

(651) 925-5620 or (800) 222-1169

Fax Us

General Fax: (651) 653-0989

HR Fax: (651) 846-5254