Leaders in High Precision Machining & Engineering

Meeting your precision machining expectations requires deep expertise, a range of advanced equipment and a history of successfully applying best practices. The Specialty Mfg. Co.’s rigorous machining standards and ISO 9001:2015 Certified processes ensure parts are repeatedly manufactured to your print specifications.

We are vertically integrated and uniquely qualified, with a team of in-house engineers and operators experienced in high precision machining to oversee and evaluate the details of your project. As part of our quality assurance protocols, we perform periodic inspections, including upon set-up and during shift changes.

From the initial design consultation through testing and our on-time shipping, you have a trusted partner for every project stage.

Machining Your Parts to Exceptional Standards

With our array of state-of-the-art CNC and mechanical equipment, we have the right machines and highly skilled personnel to run your parts to your precise specifications. Tolerances as close as .0002″ are possible, even in higher volume production runs.

Examples of machined parts we have produced include:

- Cast steel air compressor cylinders

- Gearbox housings

- Cast, steel, and aluminum valve bodies

- Steel valve spools

- Machining of vacuum molds and blow molds

A Large Inventory of Commonly Machined Materials

We are well-versed in most machinable materials and have one of the largest inventories of brass in the Midwest. The most common materials requested for high precision machining projects include:

- Aluminum

- Brass

- Eco Brass®

- Bronze

- Dura-Bar™ cast iron

- Steels

- Tool steels

- Stainless steel

- Teflon

- Nylon

- Acetal

If you require a different material, give us a call to discuss options!

In-House Engineering & Design for Manufacturing Support

If you need engineering support, we are happy to evaluate your product design. Our in-house engineers will work with you to ensure maximum design for manufacturing and assembly (DFMA) and have in-house SLA model capabilities.

Software programs we work with include:

- AutoCAD

- SolidWorks

- Feature CAM

- Pro E

- Part Maker

- Inventor

The Right Solutions to Complete Your Project

If your project requires secondary operations, we have you covered! Many services are performed in-house to ensure proper surface finish and offer the best possible lead times. We also offer additional services through trusted and qualified suppliers.

Value-added services include:

- Standard and ultrasonic cleaning

- Plating

- Abrasive blasting

- Vibratory and thermal-deburring

- Laser marking

- Heat treating

- Harperizing

- Electro-polishing

- Assembly

- Packaging

- And more

Our Precision Machining Process

Focused on Quality & Full-Service Project Support

Design Consultation

Meet with our engineers to review your print and discuss your project. If requested, we can assist with modifications to improve design efficiency.

Production & Testing

After finalizing your design, we move into production. We always provide realistic lead times to help you plan for internal product review and testing.

Finalize & Ship

Finalized production runs go through a final quality check by our team, then promptly shipped.

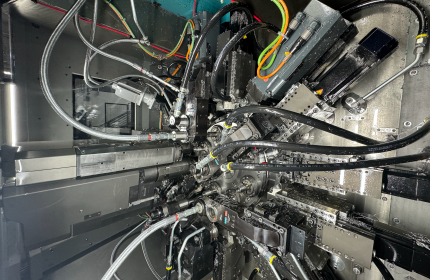

State-of-the-Art Equipment & Trusted Processes

Take a tour of our precision CNC machining operations and see our machinery and people in action.

Looking for something different? Our capabilities also include plastic injection molding, contract assembly, custom engineering services, and design and fabrication services for your project.

Contact Us to Discuss Your Project!

The Specialty Mfg. Co. is a fully integrated contract manufacturer offering machining, plastic injection molding, contract assembly, and value engineering. Call or send us a message to discuss your specific design and application!

Contact Information

Call Us

The Specialty Mfg. Co:

(651) 653-0599

New Ulm Precision Tool:

(507) 610-7770 or (800) 795-1229

SafeWay:

(651) 925-5620 or (800) 222-1169

Fax Us

General Fax: (651) 653-0989

HR Fax: (651) 925-5639