Delivering Custom Solutions Since 1975

Our New Ulm Precision Tool division specializes in building material removal and assembly machines to suit your company’s needs. Even if all you have is an abstract idea, our experienced designers can take your vision and develop a solution that improves and simplifies production processes, helping you maximize output and efficiency. If your company prefers we use specific products or brands, let us know and we will gladly honor the request.

We manage the metal and fabrication portion of your machine build and provide advice on how to improve the design. As a custom machine manufacturer that is always on top of the latest technology, we have expanded our capabilities to include adding robotics functionalities to your machine.

You are welcome to visit our shop at any time during your machine build to see the progress as it develops. We will request sample parts for tryout in the machine. This allows us to make any final adjustments and prove capability per the customer’s specifications.

Built to Perform Manual and Automated Operations

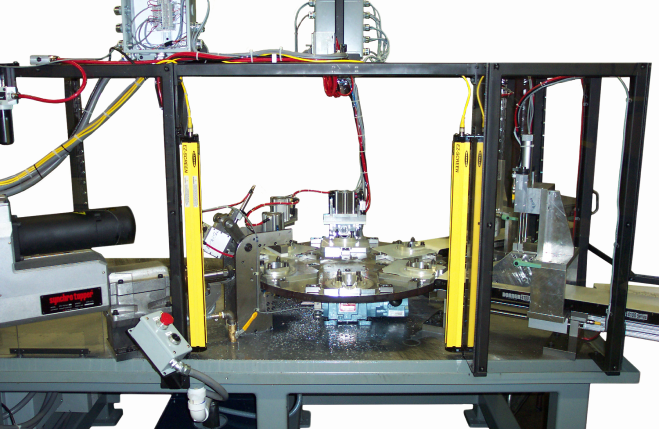

Material removal machines can be built to drill, tap, mill, counterbore, and countersink and can perform numerous other operations. The custom machines built by our team range from simple single-station machines to complex machines that use rotary index tables or in-line transfer systems. Available part clamping options include manual, pneumatic and hydraulic, depending on your needs.

Solutions to Increase Your Production Output

We build machines for a variety of applications involving the assembly of fasteners and parts made from plastic, metal and composites. These processes can be automated or semi-automated, depending on how you plan to integrate the machine with your existing system. Whether you have a plan in mind or need guidance in developing a solution to your manufacturing challenges, we can help.

How It Works

Our Engineering, Design & Fabrication Process

Consultation & Quote

Meet with our engineering team to discuss your production challenges and develop the ideal solution for your application!

Build & Quality Check

Once your design is approved, we begin building your machine. Quality checks are performed throughout production.

Deliver & Test

After conducting a final quality check, your completed custom machine is packaged and shipped to you for testing.

Featured Projects

With decades of expertise as a custom machine manufacturer, we take time to understand your challenges and work together to provide a practical and sound solution.

Large Assembly Bench

This large assembly bench was designed to accommodate using two different torque heads (not shown). Linear rails were incorporated to move the torque head assemblies from side to side so they could be positioned over the product when used. Because of the robust nature of the product assembly, the table top, linear rail assembly and frame needed to be heavy-duty.

Looking for something different? Our capabilities also include custom workholding fixtures, tool crib replacement parts, and contract manufacturing services for your project.

Discuss Your Project with Our Custom Machine Builders!

We are committed to quality and delivering solutions that help you improve productivity and profitability. Vertically integrated engineering and manufacturing capabilities allow us to provide services beyond custom machine building to be a full-service partner for all of your production needs.

Submit a contact request, and our team will contact you within one business day to discuss the details of your project.

Contact Information

Call Us

The Specialty Mfg. Co:

(651) 653-0599

New Ulm Precision Tool:

(507) 610-7770 or (800) 795-1229

SafeWay:

(651) 925-5620 or (800) 222-1169

Fax Us

General Fax: (651) 653-0989

HR Fax: (651) 846-5254