Helping You Improve Your Machining Center Efficiency

We take your vision and use our engineering and machining expertise to help you refine the details. The result is a practical, clean, and well-functioning custom workholding fixture built to the highest quality standards.

The majority of the requests we receive are manual and hydraulic workholding fixtures for use on vertical or horizontal machining centers. Common styles include tombstone, modular and trunnion.

Our in-house engineering team works with you to design and build tooling and equipment that is durable, user-friendly and easily maintained. If you require a non-standard workholding fixture or would like to discuss options for your application, we can help!

How It Works

Our Engineering, Design & Fabrication Process

Consultation & Quote

We collect details about your application, fixture type and clamping method, and valve and part/nest information.

Build & Quality Check

Our engineering, design and production departments collaborate on building your custom workholding fixture to your specifications.

Final Check & Delivery

After conducting a final quality check, your completed workholding fixture is packaged and shipped.

Partnership in Progress

Custom workholding fixtures are our specialty. For over 40 years we have helped the industrial market develop innovative and practical solutions to common machining problems.

Featured Projects

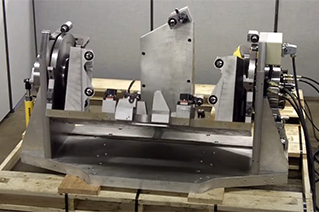

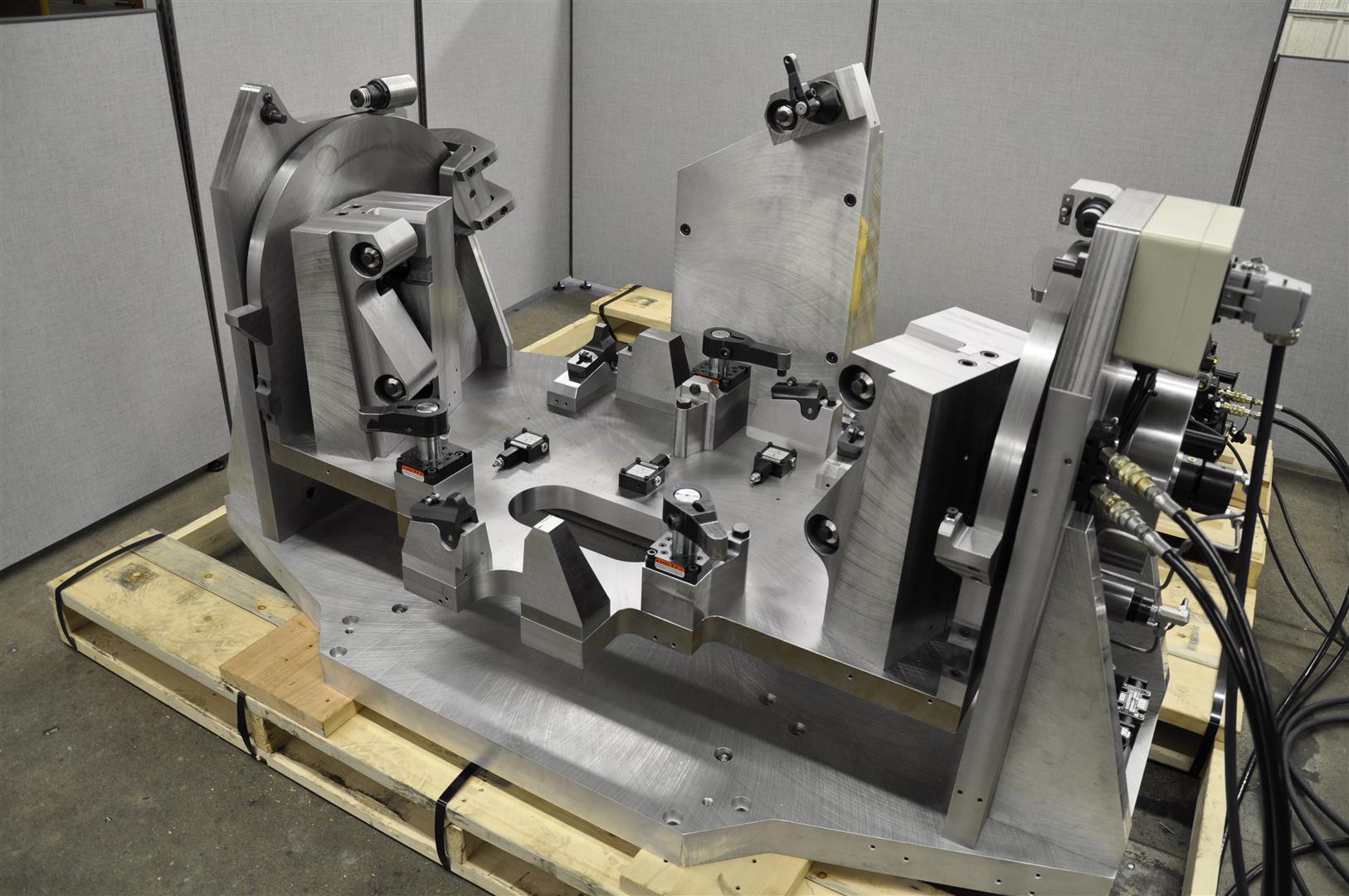

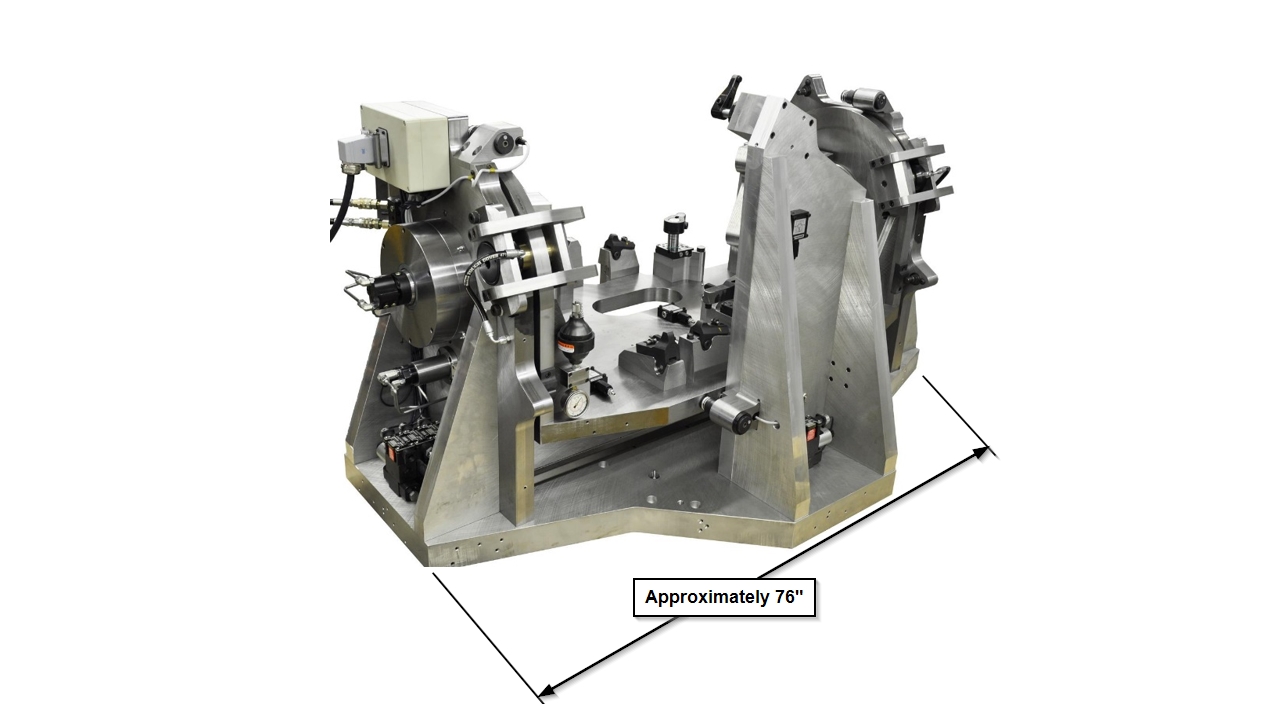

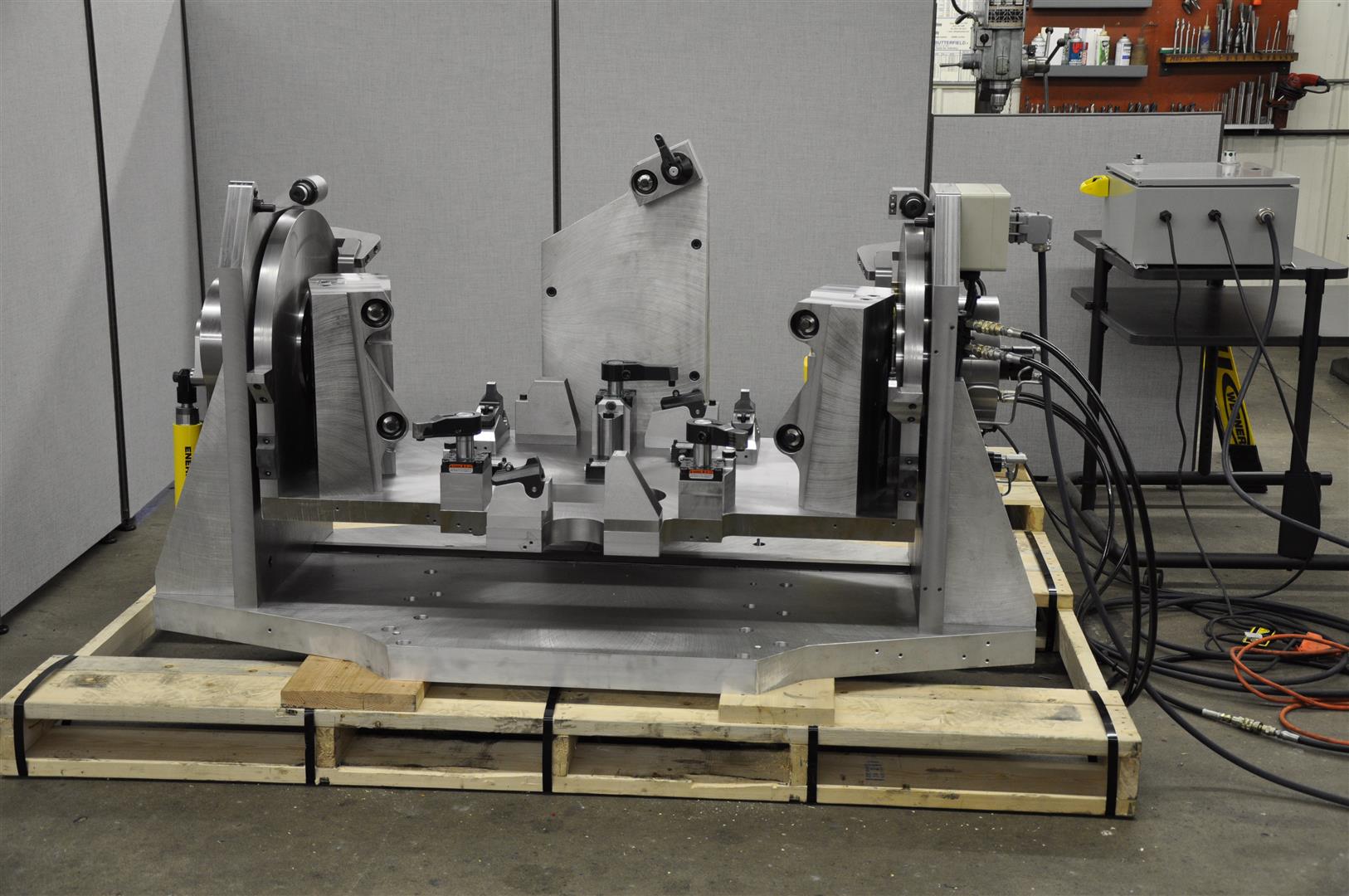

Large Trunnion Style Hydraulic Fixture

This workholding fixture was designed for use on a Mazak HCN-10800 with a 1,000 MM pallet. The fixture features multi-stage hydraulics, PLC controls integrated with the HMC controls, and multi-position trunnion-style fixturing. The fixture weighs more than 6,000 lbs., and the overall size was approximately 76″ L x 46″ W x 42″ H. The trunnion style concept allows operators the ability to machine the weldment when positioned in two different orientations.

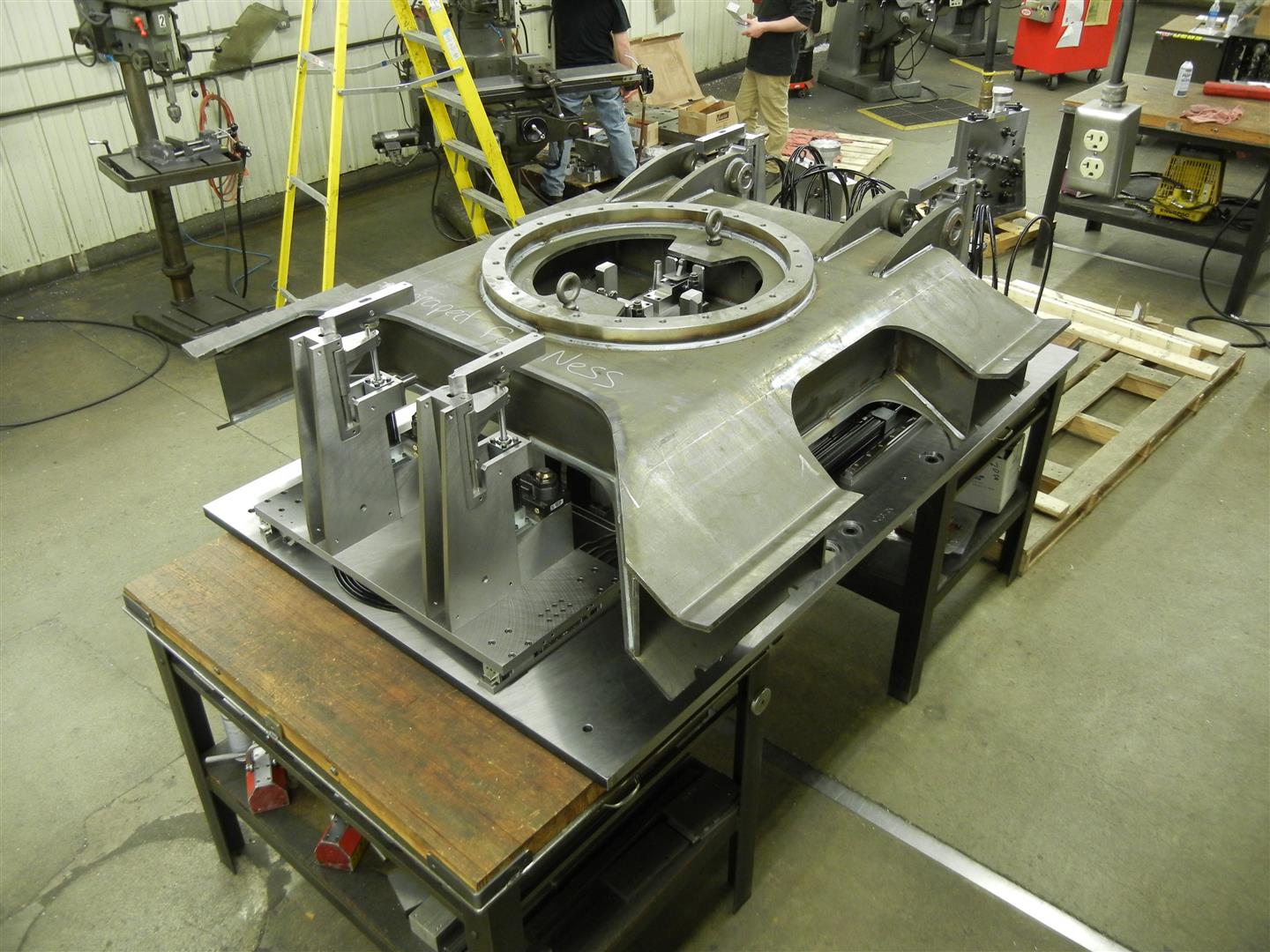

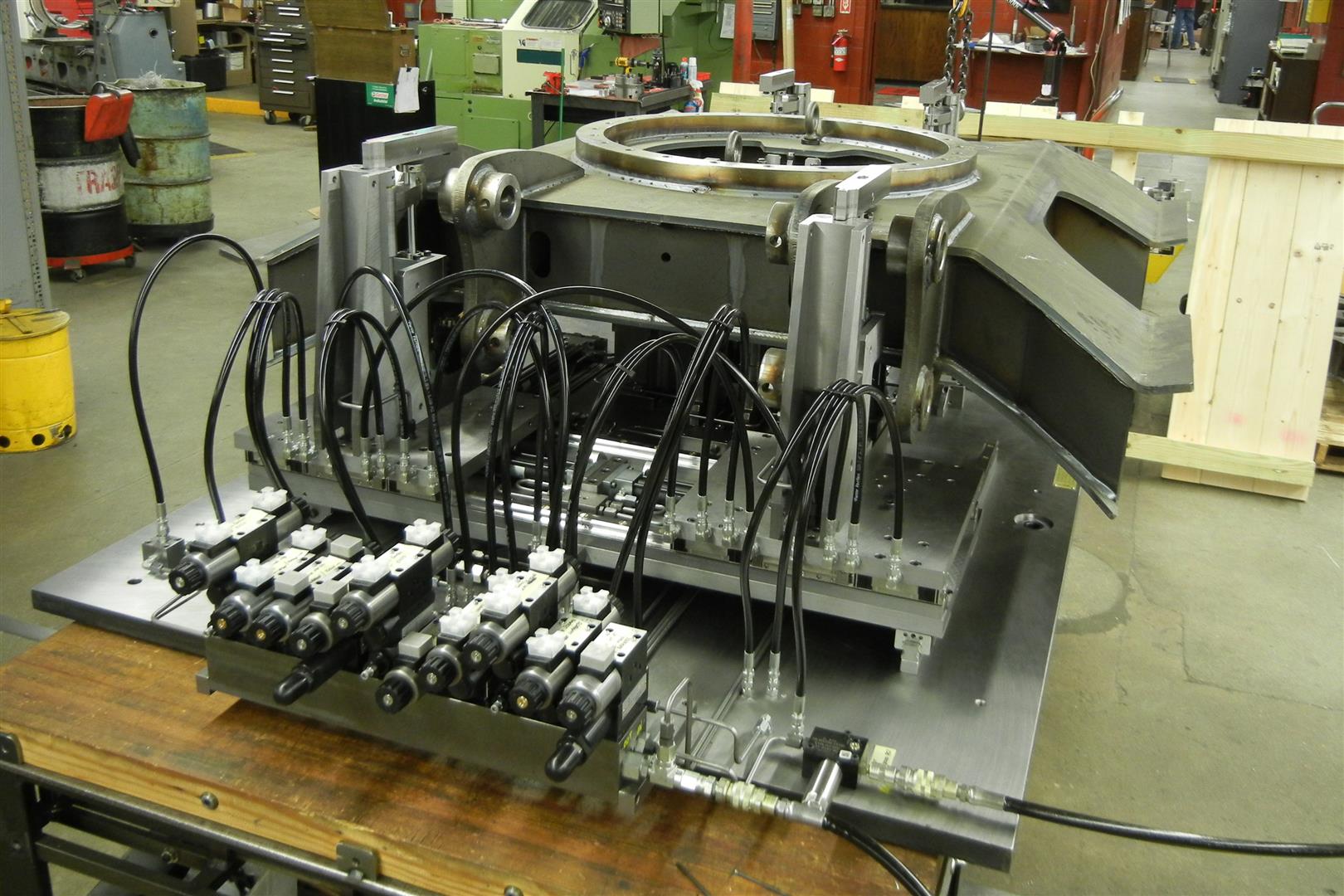

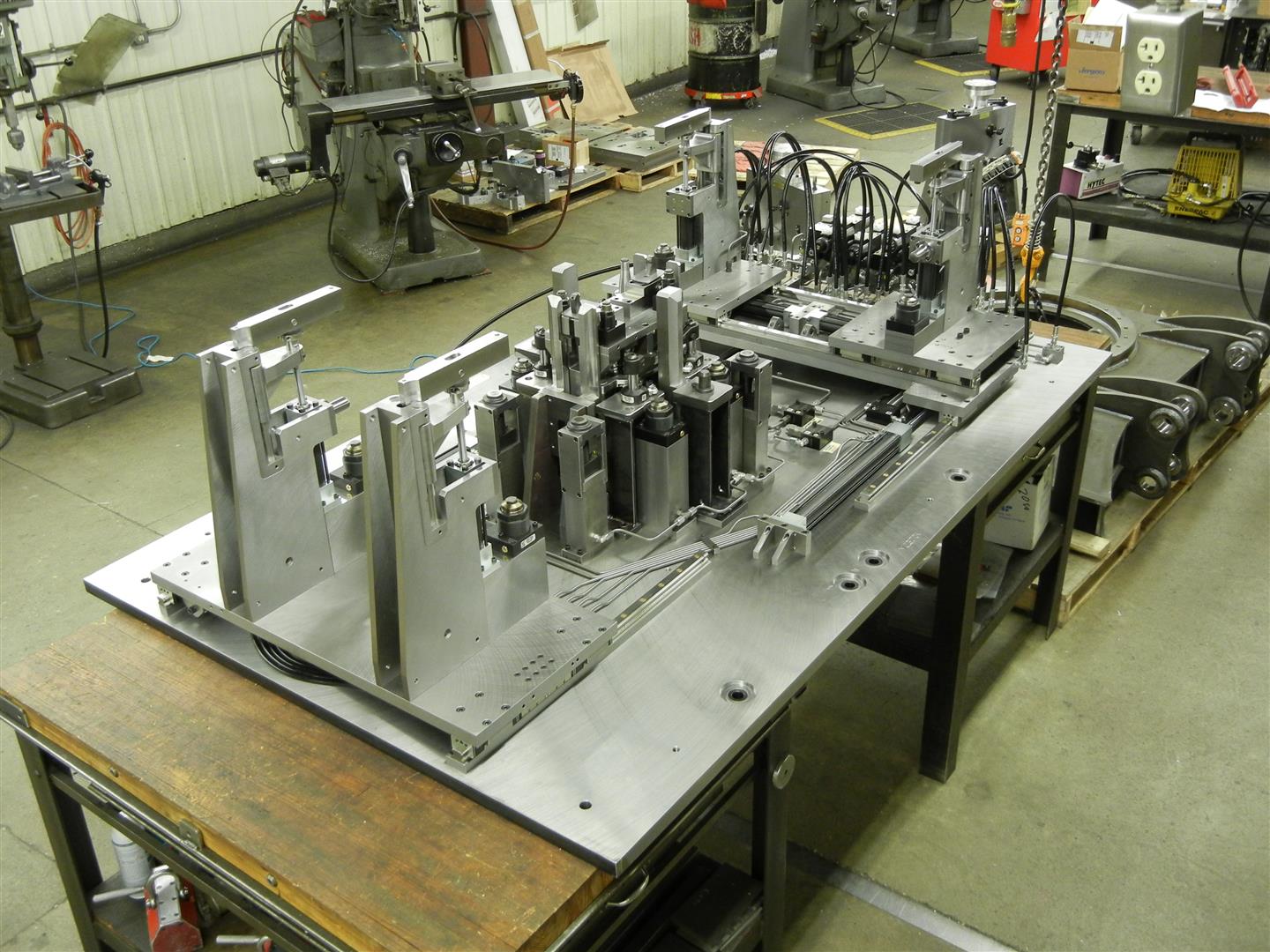

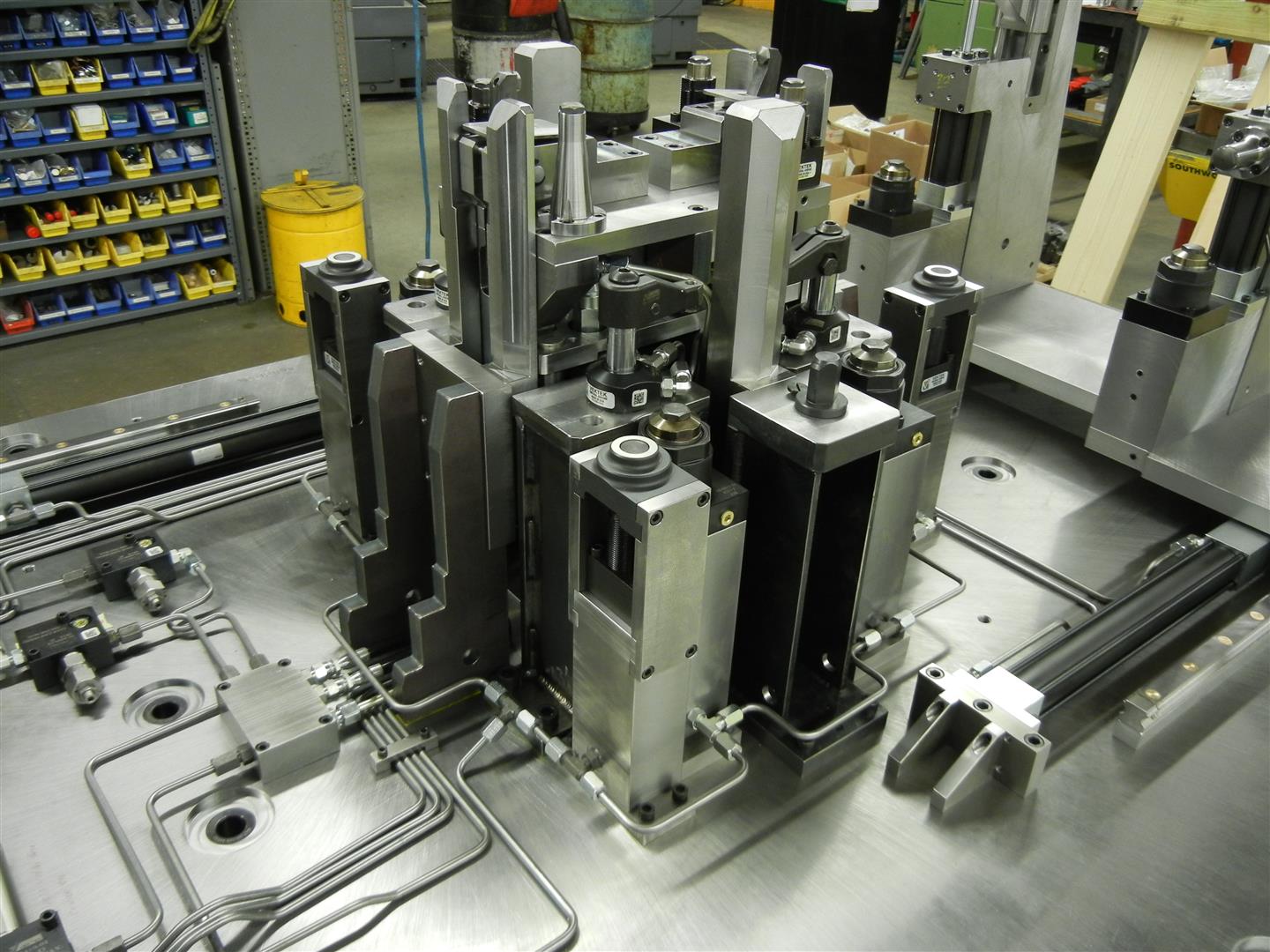

Large Weldment Machining Fixture

This large multi-stage hydraulic clamp machining fixture holds multiple versions of a weldment. Linear slides and cylinders are controlled by a stack of solenoid valves located on the fixture. Sequence valves were also used for energizing the hydraulic work supports and swing clamps in the proper order. The solenoid valves were integrated and actuated by the controls of the large VMC the fixture was used on.

The unique fixture design uses linear slides and hydraulic cylinders to move the clamps and work supports into different positions, which accommodates multiple weldment configurations. The design eliminated the operator’s responsibility for changeover, ultimately reducing setup time and any chance for human error.

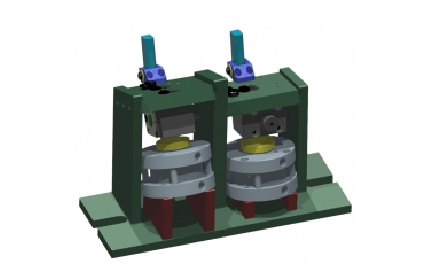

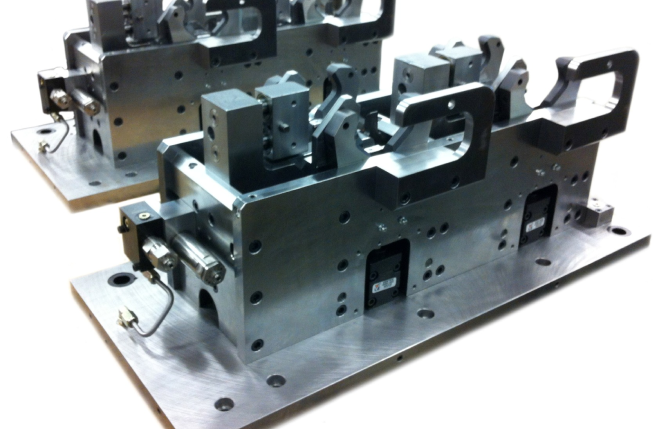

Modular Hydraulic Tombstone Fixture

This modular-style hydraulic tombstone fixture has a rotary union on top. The modular sub-fixtures are located on the tombstone using ball lock locators and retainers. Hydraulic oil is supplied to the aluminum sub-fixtures through flush-mount couplers.

Because of the modular design, operators easily change out the sub-fixtures on the tombstone, giving them added flexibility to meet production demands. The ball lock retainers are extremely accurate and rock solid in securing the sub-fixtures to the tombstone.

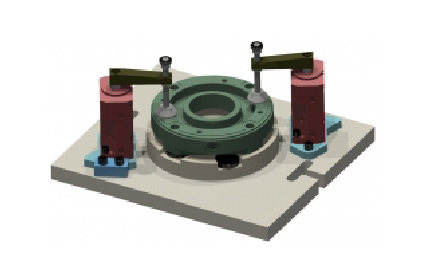

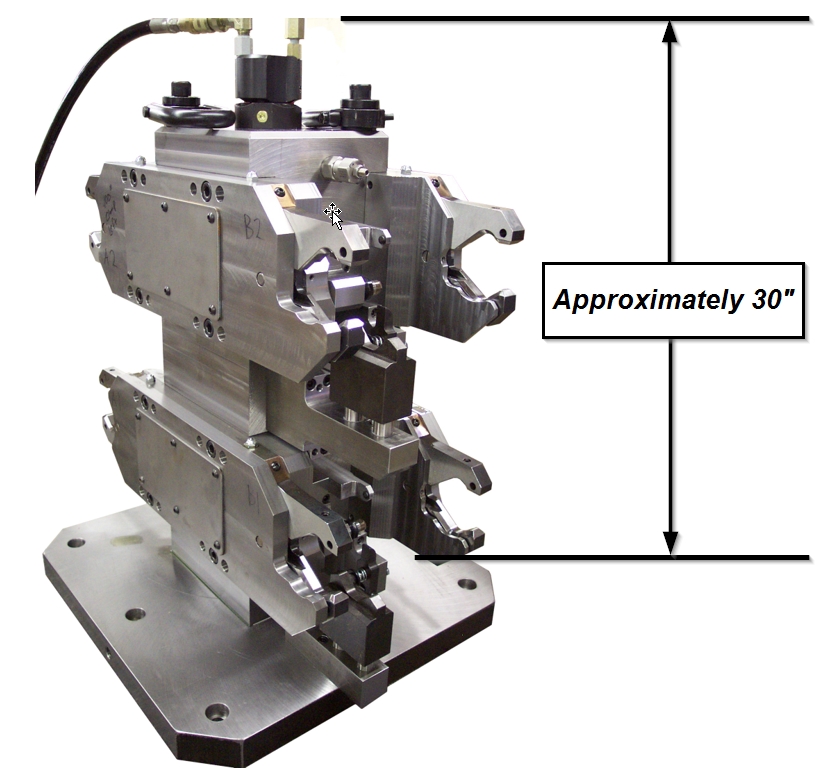

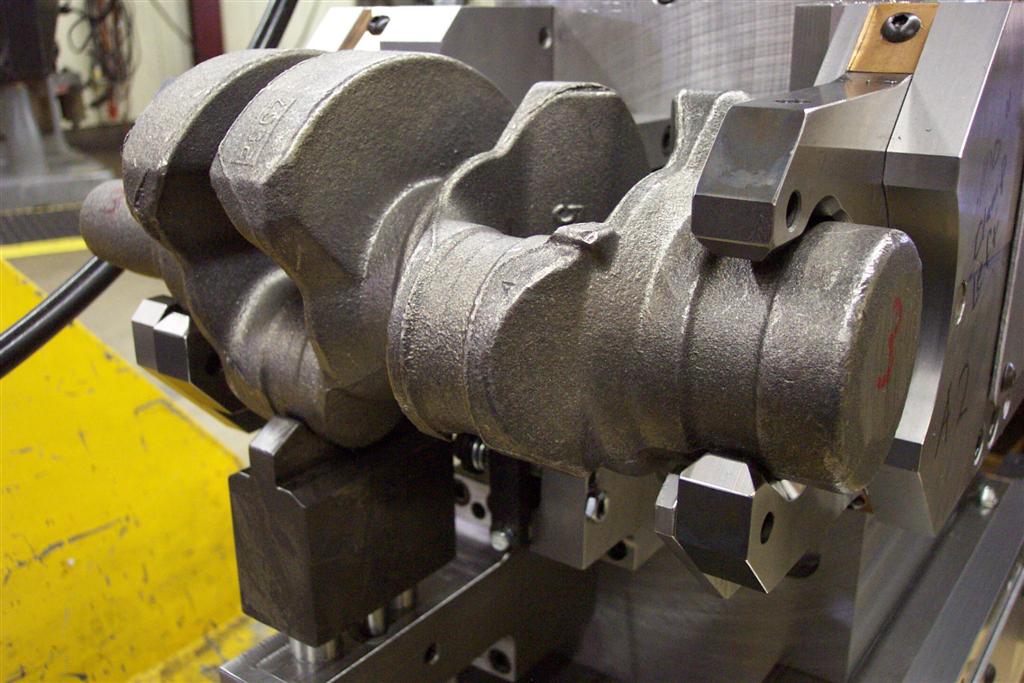

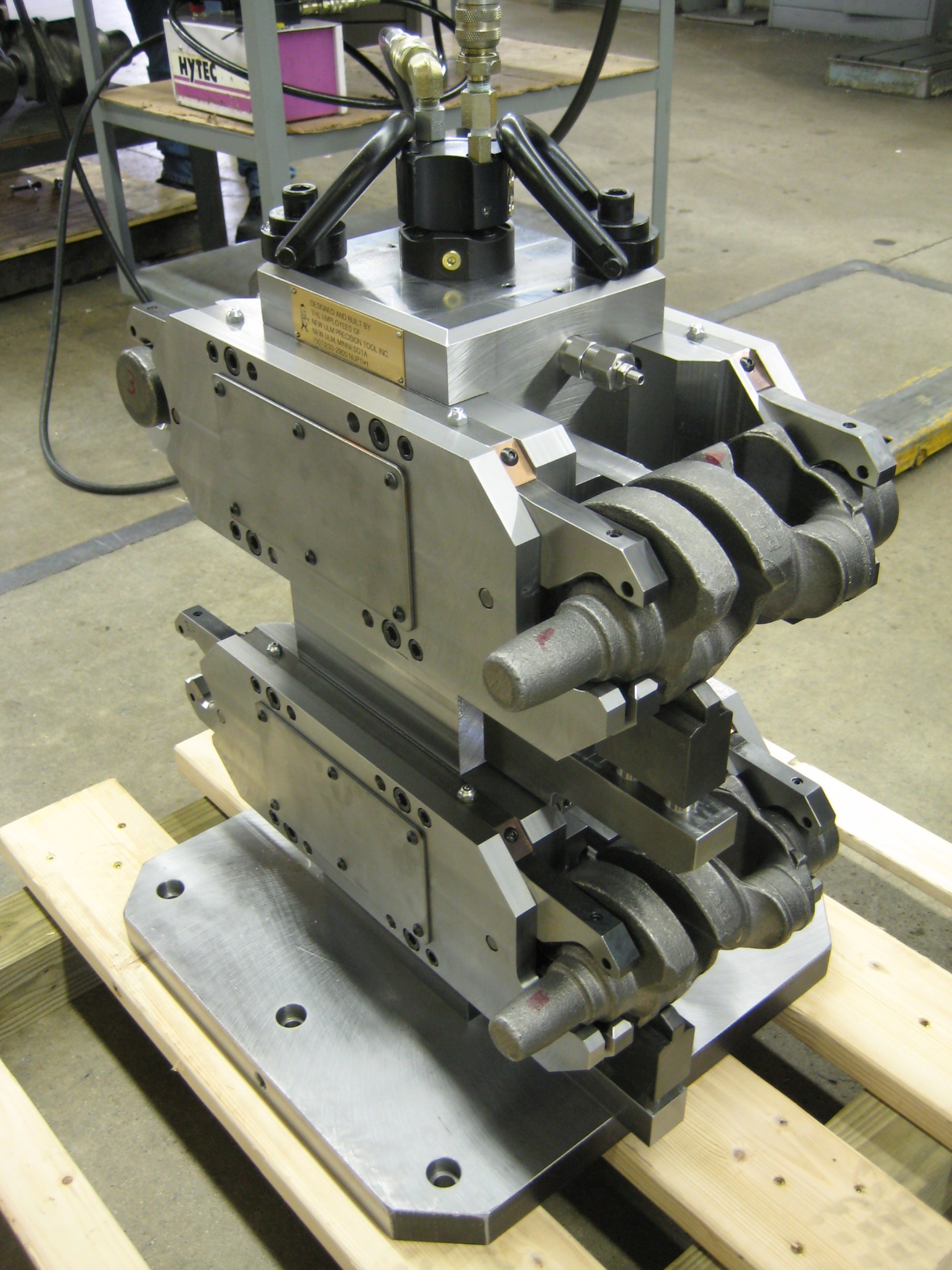

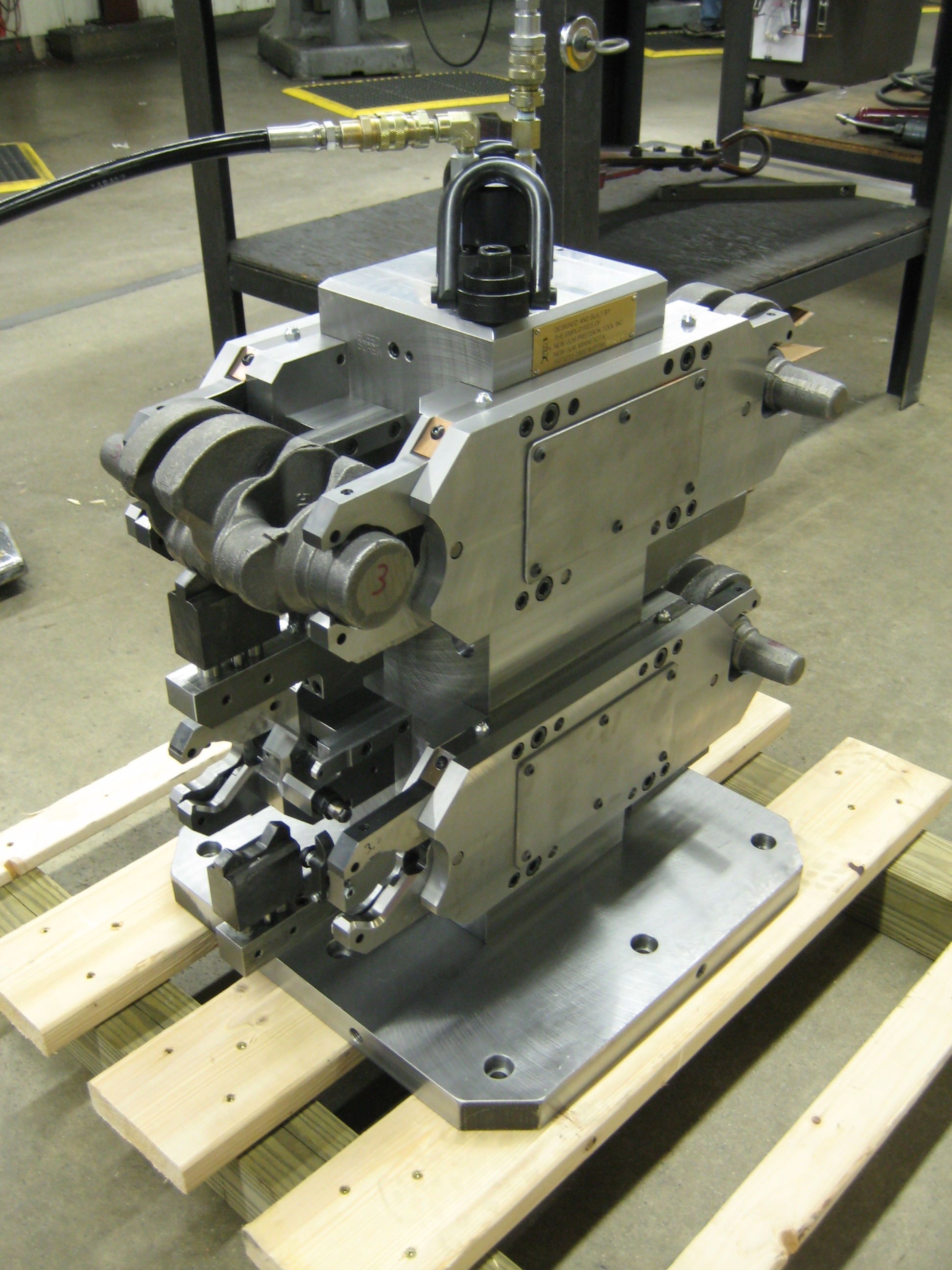

Self-Centering Crankshaft Machining Fixture

This self-centering hydraulic clamp tombstone fixture holds four crankshafts for machining. The fixture is built for mounting to a 400mm pallet and used in an HMC. The hydraulics are fed live from the top using a rotary union mounted on the top of the fixture. The operator can load all four stations, and spring pushers hold the castings against the datums until hydraulic pressure is applied (hands-free load).

The repeatability and impressive rigidity of this self-centering fixture helped the customer reduce their machining costs by not only lowering the run time, but also greatly reducing scrap. They described the design as solid and easy to maintain.

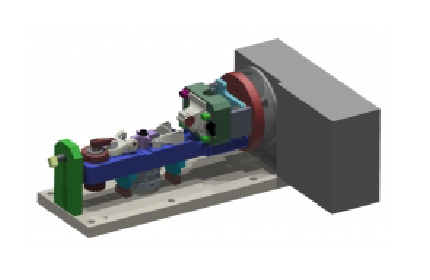

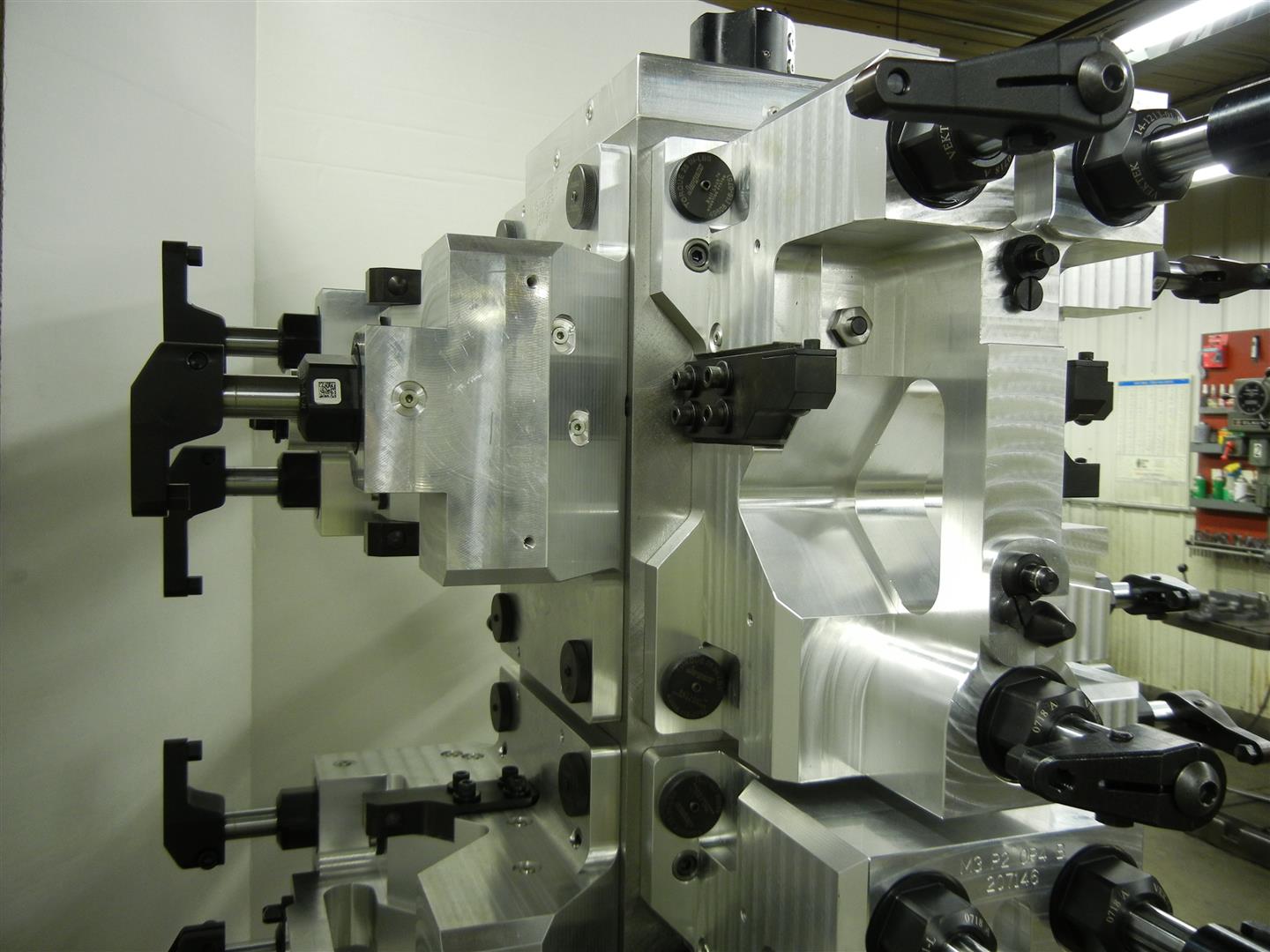

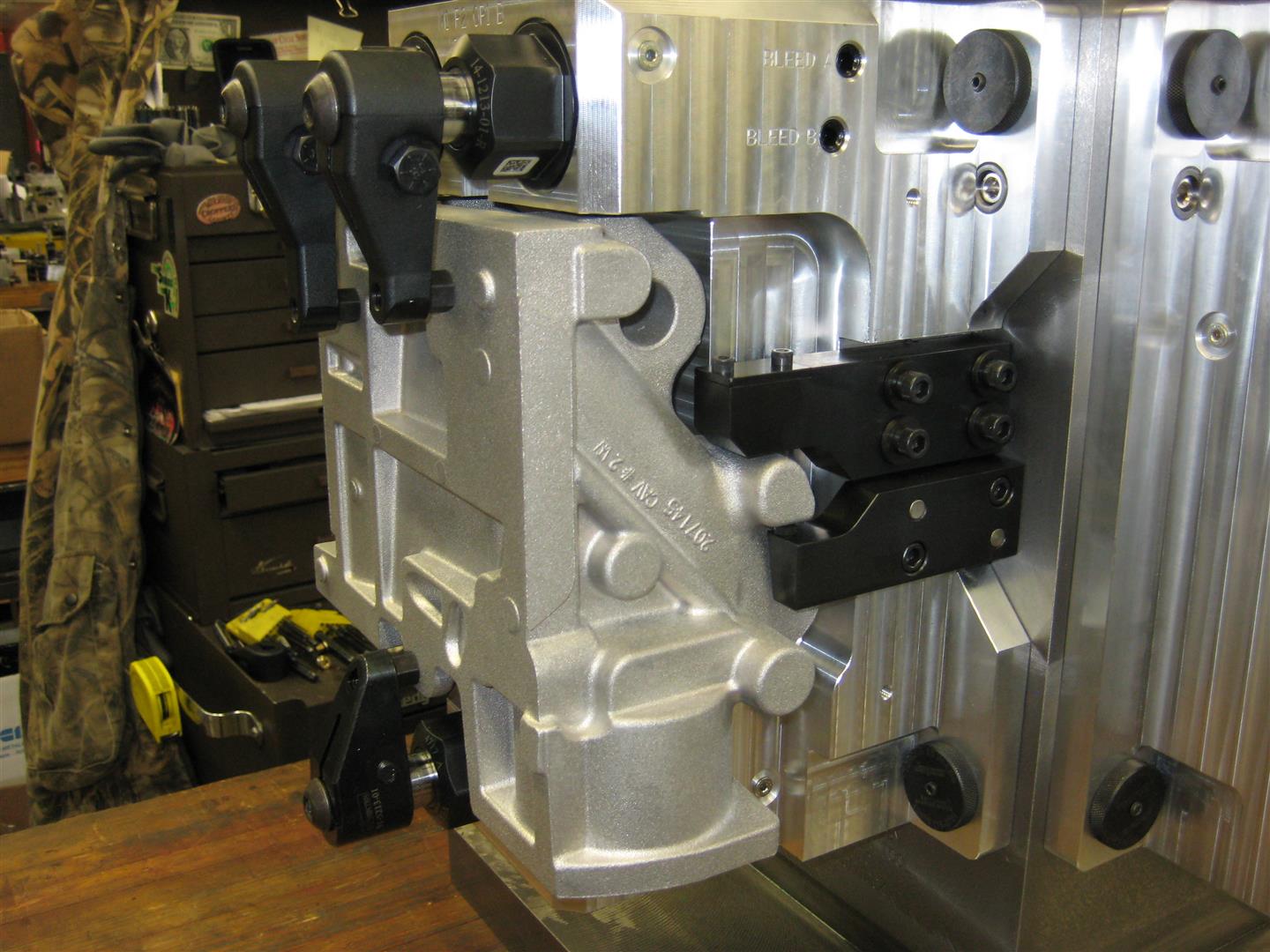

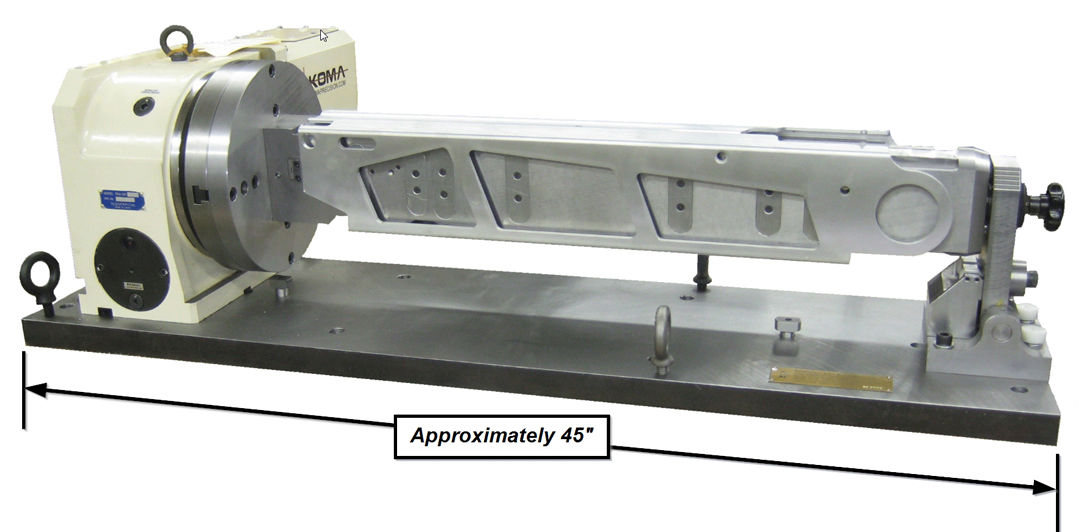

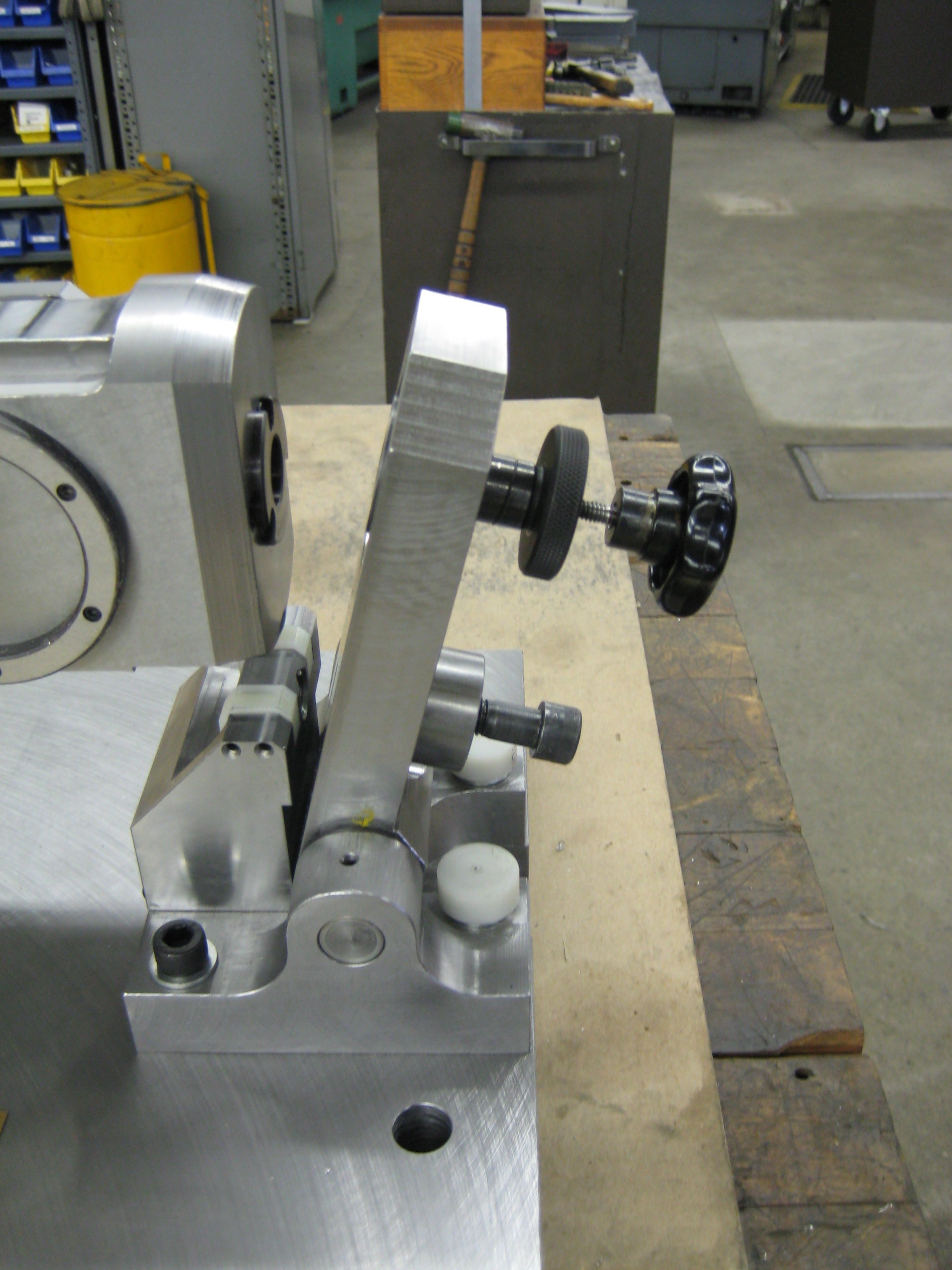

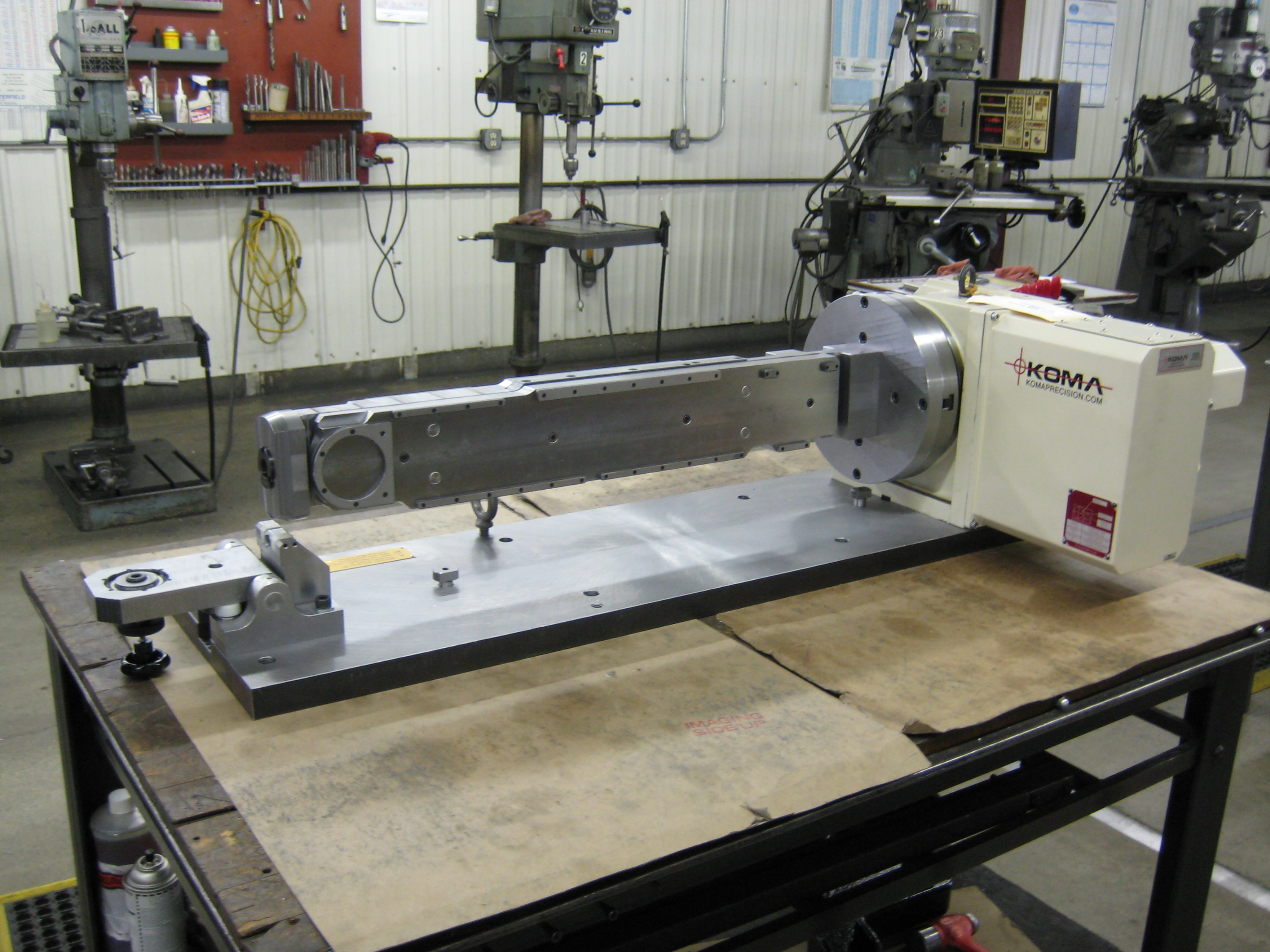

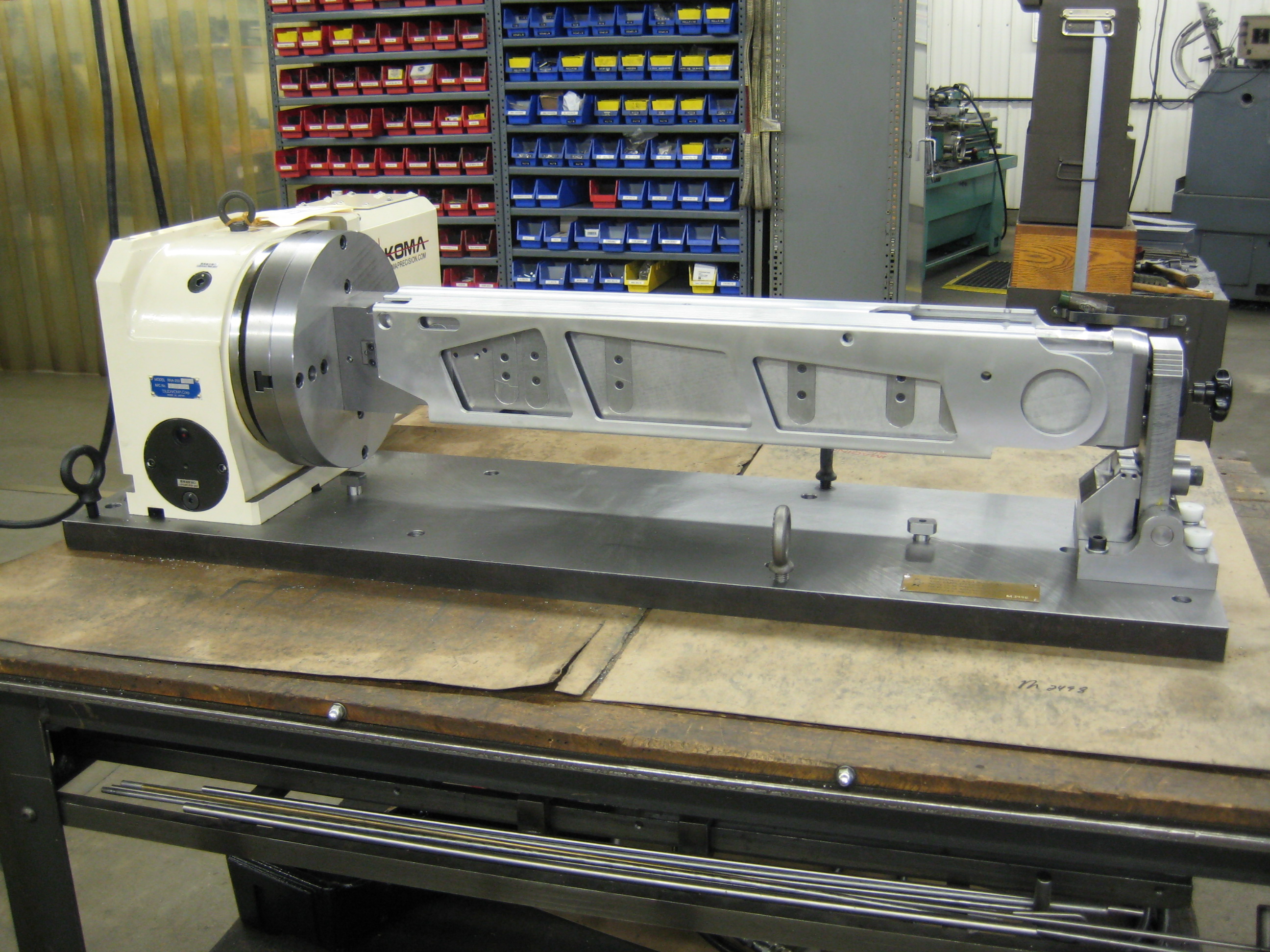

Trunnion Fixture with Drop Away Tailstock

This hydraulic clamp trunnion fixture features a drop-away tailstock. It is used on a VMC, and the hydraulic supply is plumbed through the center of the rotary indexer to a rotary union mounted on the backside.

Hydraulic cylinders within the trunnion “expand,” forcing clamp plates outward. This secures the aluminum extrusion for the machining process. The fixture was designed to accommodate three different extrusions with common width/height dimensions but differences in overall length.

The drop-away tailstock is simple and solid. Combined with the internal hydraulics for clamping, it allows the operator to quickly change out the cast tube, ultimately reducing cycle time. The rigidity added with the tailstock results in lower run time and reduced scrap.

Looking for something different? Our capabilities also include tool crib replacement parts, custom machine building, and contract manufacturing services for your project.

Discuss Your Project with an Engineer!

Whether you need a standard fixture or a unique solution, our team is here to help. As a vertically integrated manufacturer, our capabilities extend beyond custom workholding fixtures to meet all of your production and machining needs.

Submit a contact request, and our team will contact you within one business day to discuss the details of your project.

Contact Information

Call Us

The Specialty Mfg. Co:

(651) 653-0599

New Ulm Precision Tool:

(507) 610-7770 or (800) 795-1229

SafeWay:

(651) 925-5620 or (800) 222-1169

Fax Us

General Fax: (651) 653-0989

HR Fax: (651) 846-5254